Our Capabilities

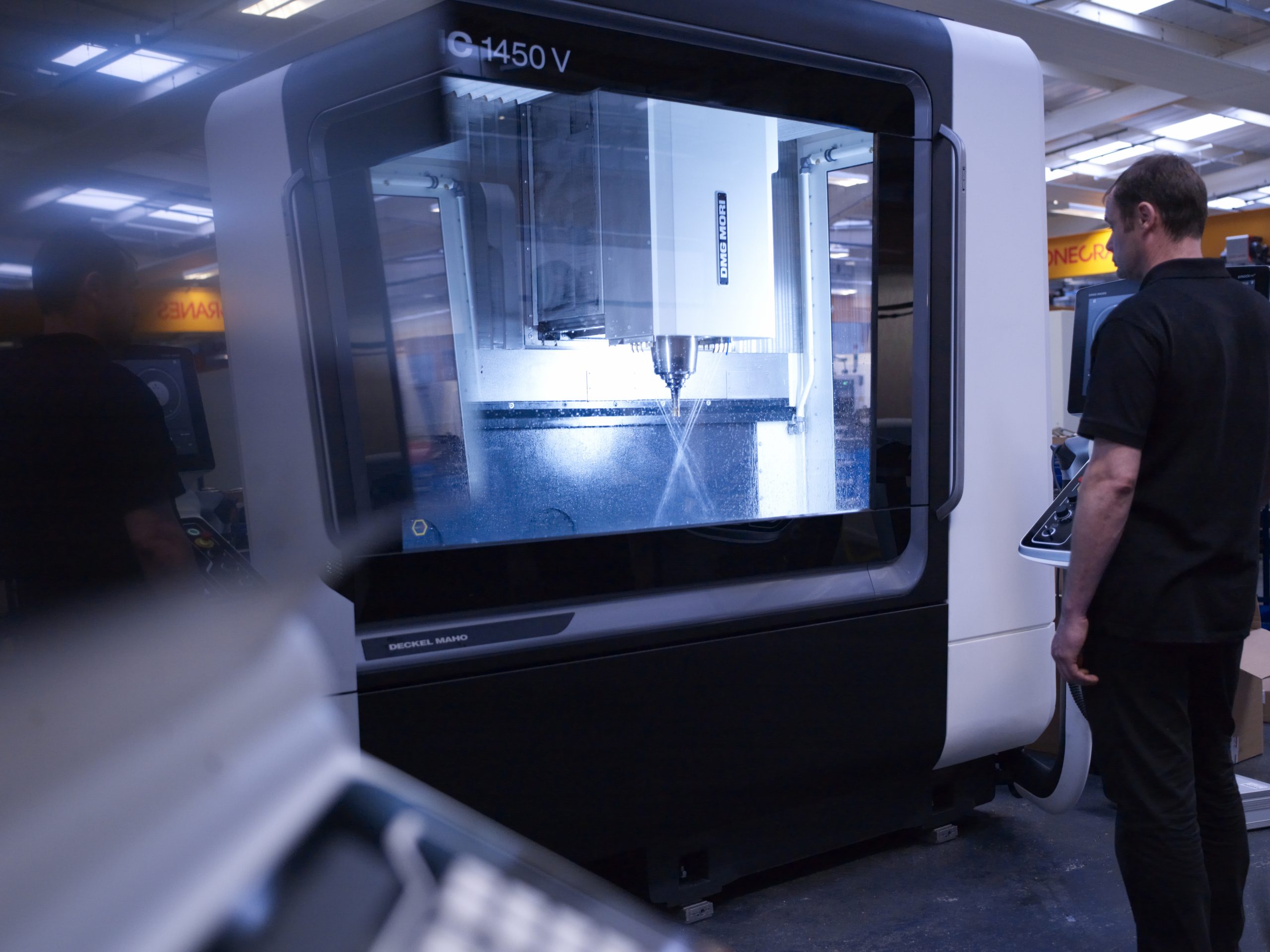

At Chirton Engineering we are continually investing in our plant and equipment. Our latest investment has taken place during November 2023, with a pair of DMG Mori milling machines.

Plant list

CNC Multi-tasking Machine

- 1 x Mazak Integrex i300s 1500mm Bed (Universal) Twin Spindle. X=615mm Y=250mm – Z=1585mm – W=1574mm

- 1 x Mazak Integrex i300 1500mm Bed (Universal). X=615mm Y=250mm – Z=1585mm – W=1574mm

CNC Turning

- 1 x Doosan Puma 700LM Mill/Drill – Max Swing 1030mm, Max Turn Dia 900mm, 3200mm Max Turn Length, 6.3 tonne max weight

- 2 x Victor V-Turn 46-Swing 850mm or 550mm Over Bed, 1700mm Between Centres

- 1 x Victor V-Turn 40-Swing 800mm or 520mm Over Bed, 2200mm Between Centres

- 1 x Doosan Puma 400 Max Swing 700mm, Max Turn Dia 560mm, 2000mm Max Turn Length

- 2 x Victor V-Turn 36-Swing 700mm or 450mm Over Bed, 1500mm Between Centres

- 1 x Doosan Puma 3100M Mill/Drill Max Swing 850mm, Max Turn Dia 420mm, 790mm Max Turn Length

- 1 x Doosan Puma 2600LMB Mill/Drill Max Swing 480mm, Max Turn Dia 376mm, 1245mm Max Turn Length

- 1 x Doosan Puma 5100LMB Mill/Drill – Max Swing 650mm, 2000mm Between Centres

- 2 x DMG Mori NLX 2500Y/700 with Sub spindle and Y Axis Milling. Max Turn Dia 366mm, Max Turn Length 705mm

- 2 x DMG Mori NLX 2000Y/500 with Y Axis Milling & Bar Feed. Max Turn Dia 348mm, Max Turn Length 510mm

- 1 x XYZ Pro-Turn SLX555 Swing Over Bed 560mm x 1750mm

- 1 x XYZ 250TC Dia 250mm x 234mm Travel

- 1 x XYZ 200TC Dia 200mm x 350mm Travel

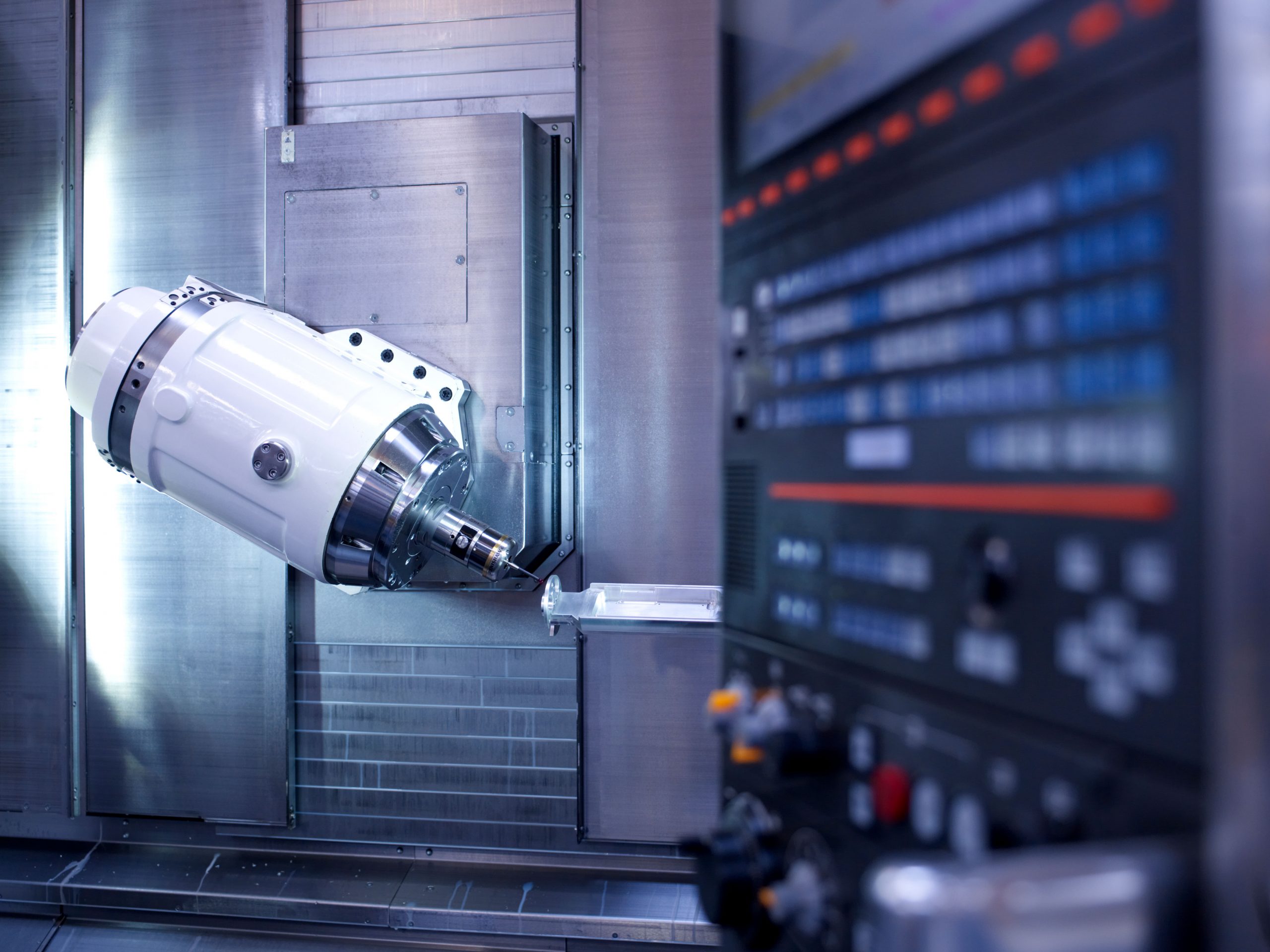

CNC Milling

- NEW – 1 x DMG Mori M2 Pro – 4 Axis Milling Machine: X=1100mm, Y=550mm, Z=510mm

- NEW – 1 x DMG Mori CMX 70U – 5 axis with PH150 Automation Cell: X=750mm, Y=600mm, Z=520mm

- 1 x Mazak VTC800/30 SR 5 Axis, Table Working Capacity X=3500mm, Y=820mm, Z=720mm

- 1 x DMG DMF180/7 5 Axis X=1800mm Y=700mm Z=700mm

- 1 x XYZ 3010 VMC Travel X=3000mm Y=1000mm Z=800mm with 4th Axis

- 2 x DMG Mori 1450 V Series Travel X=1450mm – Y=700mm – Z=550mm with 4th Axis

- 1 x Doosan DNM 750L II 1450 Travel X=2160mm – Y=762mm – Z=650mm with 4th Axis

- 3 x XYZ 1510 VMC Travel X=1500mm Y=600mm Z=600mm with 4th Axis

- 2 x XYZ 1020 VMC Travel X=1020mm Y=520mm Z=546mm with 4th Axis

- 2 x XYZ 710 VMC Travel X=710mm Y=500mm Z=450mm with 4th Axis

Pro Milling

- 1 XYZ SMX SLV 3000 CNC Milling Machine

Centre Lathe

- 1 x Colchester Triumph 2500 830mm x 160mm or Dia 350mm x 1500mm

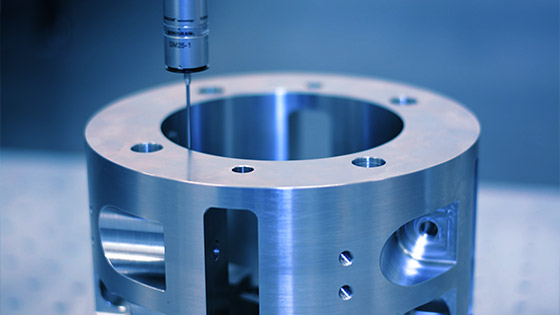

Inspection Equipment

- 2 x Mitutoyo CNC CMM Crysta – Apex S122010:- X=1200mm, Y= 2000mm, Z= 1000mm

- 1 x Mitutoyo CMM Crysta Plus – S9108:- X= 900mm, Y= 1000mm, Z= 800mm

- 1 x Mitutoyo CNC CMM Crysta Apex S574:- X= 500mm, Y= 700mm, Z= 400mm

- 1 x Aberlink Xtreme CMM :- X= 300mm, Y= 300mm, Z= 200mm

- 1 x Baty R400 Horizontal Profile Projector

- 1 x Future-Tech FR-X1L Digital/Motorised Material Hardness Tester (Rockwell/Brinel)

- 1 x Gagemaker System with MicTrack

- 2 x Mitutoyo Surface Finish Tester

- 5 x Mitutoyo LH600-E Digital Linear Height Gauge

- 1 x Jib Crane SWL 1.00 Tonne

- 1 x Sylvac Scan S145 Optical Shaft Measurement Ø145 x 615mm

- 1 x Trimos THV In House Gauge Calibration 100mm Range (UKAS Calibrated)

Traceability and Identification

- 2 x ProPen P5000 Engraving Machine

- 1 x DP4500 Rotary Axis

- 1 x Electrox Laser Marking Machine

Production Support Equipment

- Overhead Crane to cover Heavy Machine Production Area 20 metres x 36 metres SWL x 6.3 Tonne

- 4 x Jib Cranes SWL 1.25 Tonne to cover Small machine sections

- Turbex CL800 Spray Wash Parts Degreaser Washing Machine

- Waytrain WH360AE Twin Column Vice Feed Automatic Bandsaw

- Ultrawave IND5040D Ultrasonic Bath

- 1 x Starrett HB400 Horizontal Profile Projector

- Hypermill CAD/CAM Software & Tool Simulation Programme

- Solidworks Solid Modelling/CAD Software

Smart Factory Solutions/Manufacturing Data Management

- Progress Plus ERP system

- Seiki scheduling software

- Seiki machine monitoring

- Seiki shop floor data collection